РАСПЛАВЫ

2 · 2019

УДК 549.5+544.31

A NEW MULTIPURPOSE THERMODYNAMIC DATABASE FOR OXIDE SYSTEMS

© 2019 г. E. Yazhenskikha, *, T. Jantzenb, K. Hackb, M. Müllera

aForschungszentrum Jülich GmbH, Institute of Energy and Climate Research (IEK 2), Jülich, Germany

bGTT Technologies, Herzogenrath, Germany

*e mail: e.yazhenskikh@fz juelich.de

Received 02.07.2018

After completion 09.07.2018

Accepted for publication 15.07.2018

A new thermodynamic database for oxides has been developed in order to perform calcu

lations and predictions of equilibria for various scientific and industrial applications (slags,

ashes, glasses, minerals, ceramics, refractories, etc.). The database containing all known

phases (gas, stoichiometric compounds, solid and liquid solutions) for combinations of

27 different components provides proper descriptions for many different processes under

varying conditions (temperature, pressure, overall composition) including interactions be

tween materials and environments, and thus supports the development of new materials.

Keywords: thermodynamic assessment, CALPHAD modelling, database development,

phase equilibria, oxide systems, associate model, calculations of thermodynamic properties.

DOI: 10.1134/S0235010619010237

INTRODUCTION

Thermodynamic properties of complex oxide systems containing high amounts of silica,

alumina, iron oxides, alkali earth and alkali oxides, for which the measurements are experi

mentally difficult due to high temperatures, high volatility, high viscosity, etc., can be calculat

ed and predicted by thermodynamic modelling on the basis of reliable experimental data and

appropriate Gibbs energy models for the various phases. The available commercial databases

are not always sufficient to describe the complete system containing slag, ashes, biomass, gas,

coal etc., so a new database is necessary. In the past 15 years an oxide database has been devel

oped in the framework of a series of national projects (concerning coal gasification and combus

tion processes) supported by funding from the German government and industrial partners [1].

THERMODYNAMIC MODELS

Detailed reports on several of the assessments of subsystems can be found in respective pub

lications e.g. [2-4]. The thermodynamic database has to contain reliable descriptions of all

relevant phases (gas, stoichiometric compounds, solid and liquid solutions) in order to per

form proper calculations and predictions of thermodynamic properties and phase constella

tions. Stoichiometric compounds, i.e. solids with a fixed chemical formula such as Al2O3 or

CaSiO3 are modelled with a temperature dependent G°(T) function:

G° = A + B · T + C · T · ln(T) + D · T2 + E · T3 + F/T.

(1)

In case of non stoichiometric phase, i.e. solid and liquid solutions, the molar Gibbs energy of

ref

the solution is a three term expression with contributions of the reference part(G

),

the ideal

id

ex

(G

)

and the excess

(G

)

part as:

ref

id

G

m

=

G

+

G

+

G

ex.

(2)

Depending on the solution model chosen the three parts take on different mathematical form.

A new multipurpose thermodynamic database for oxide systems

117

T, °C

2500

Slag

[6]

2300

2100

1900

1700

C2S_C3P

1500

1300

C2S_C3P + C3P(s2)

1100

C2S_C3P + C3P(s)

C2S_Prime

900

Ca5P2SiO12 + Ca3(PO4)2(s)

700

Ca5P2SiO12

500

Ca7P2Si2O16

C2S_Prime + Ca2SiO4

300

0

20

40

60

80

100

wt % Ca3P2O8

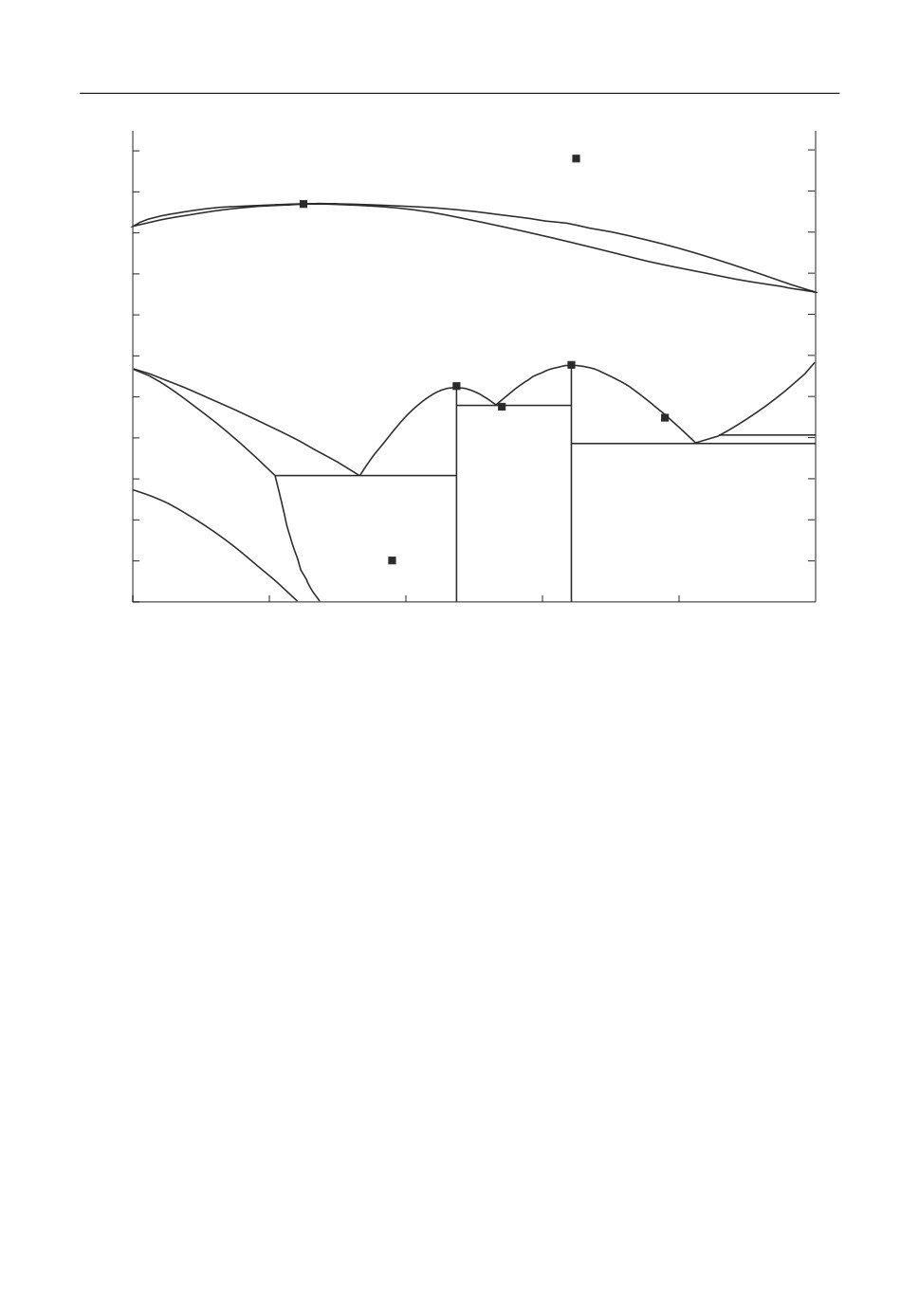

Fig. 1. Isopleth Ca2SiO4-Ca3P2O8.

Solid solutions are usually treated using the multi sublattice approach. For example, the

high temperature modifications of dicalcium silicate Ca2SiO4 and tricalcium phosphate

Ca3P2O8 have the same structure and Pearson symbol [5]. According to the high temperature

phase equilibria investigations [6] in the quasi binary system Ca2SiO4-Ca3P2O8 a continuous

series of solid solutions is formed at steelmaking temperatures. This is termed the C2S C3P

phase with the phase formula (Ca2+)3(Ca2+,Va)(P5+,Si4+)2(O2-)8. The first and fourth sublattic

es have fixed occupancy, while the third sublattice can be occupied by phosphor and silicon

cations and the second sublattice represents an interstitial position. This formula allows de

scribing the unsymmetrical end members Ca2SiO4 (C2S) and Ca3P2O8 (C3P) and the contin

uous transition between them. As shown in Figure 1, the solid solution between the two end

members C2S and C3P is complete above 1500°C.

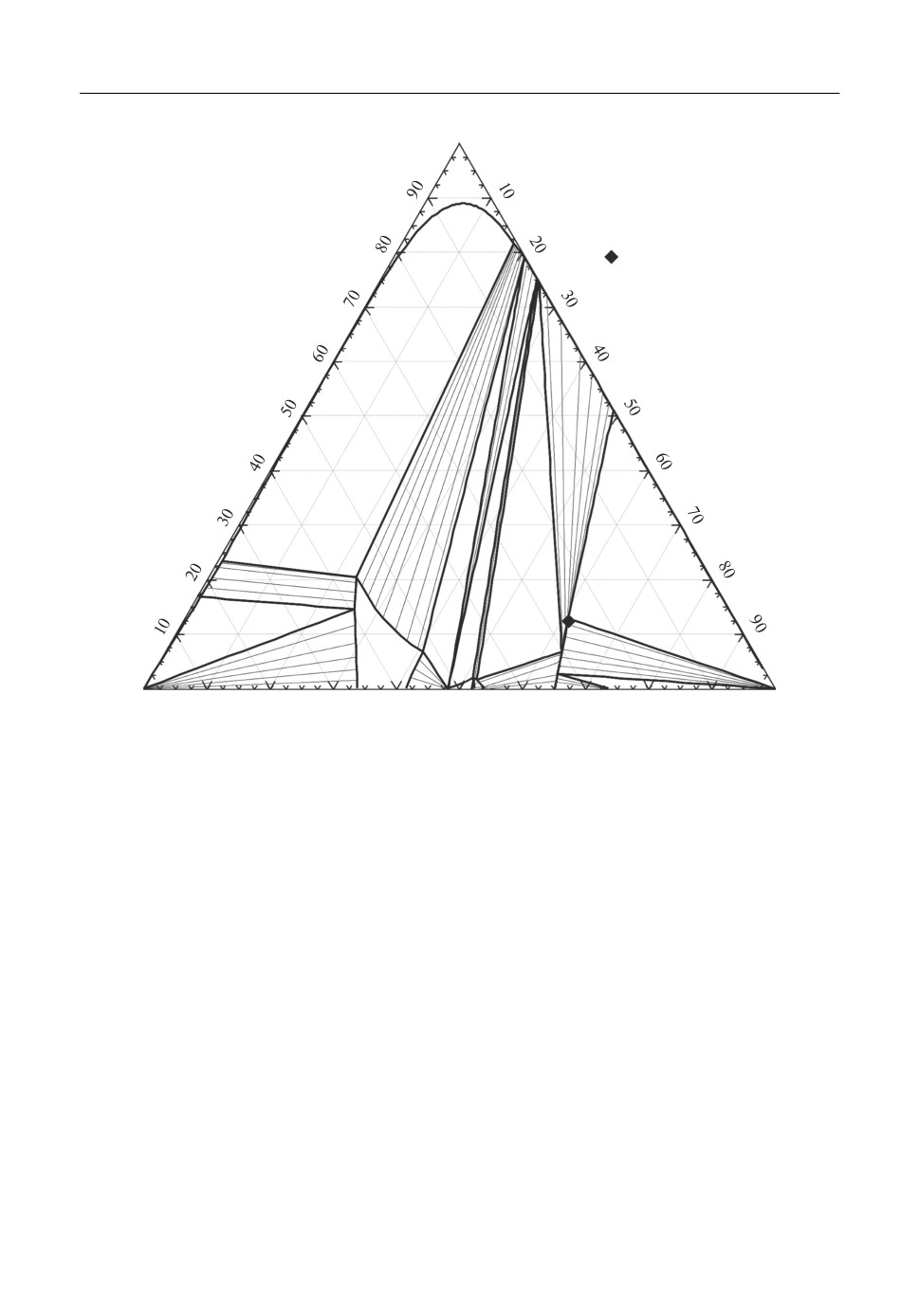

Chromium, manganese and magnesium cations are introduced on the second sublattice to

describe their experimentally determined solubilities in C2S-C3P. Eke and Brett [7] reported

considerable solubility also of Vanadium oxide in the α Ca2SiO4. The positioning of V as a pen

tavalent cation on the third sublattice leads to a good reproduction of the experimental solubility

as shown in Figure 2. The full thermodynamic description of the phase C2S-C3P is presented

using the following formula (Ca+2)3(Ca2+,Mg2+,Cr3+,Mn2+,Va)(P5+,Si4+,V5+)2(O2-)8.

The liquid phase (slag), which exhibits short range ordering as well as ranges of immiscibil

ity, is modelled using the non ideal modified associate model according to Spear and Bes

mann [8]. The model was successfully applied for many types of systems with strong interac

tions [2-4]. Moreover, this model can give a reliable phase internal distribution of associate

species, which is consistent with experimentally determined Qn species distributions [9]. Fur

118

E. Yazhenskikh, T. Jantzen, K. Hack, M. Müller

V2O5

Slag

[7]

Slag

C2S_C3P

Slag

SiO2

90

80

70

60

50

40

30

20

10

CaO

CaSiO3(s2)

Ca3SiO5

percent by weight

Fig. 2. Isothermal section at 1500°C in CaO-V2O5-SiO2 system.

thermore, the associate model representing the internal structure of the molten slag provides

an excellent basis for the modelling of melt viscosity [9]. The liquid component oxides as well

as binary and ternary associate species are considered as solution components. In addition, in

teractions between species were introduced in order to fine tune the thermodynamic descrip

tion especially in regions of immiscibility. The excess term of G (Eq. (2)) is expressed by

Redlich-Kister polynomials. The associate species were given the same stoichiometries in

comparable systems in order to provide a handle for their use in multi component systems. As

an example of consistent description, all P2O5 containing liquid species are listed in Table 1.

ASSESSMENT OF THERMODYNAMIC PARAMETERS

According to CALPHAD type modelling all available experimental data (phase equilibria,

mixing properties, activity, etc.) are critically analysed in terms of their consistency. Each

phase in the system is treated by an appropriate Gibbs energy model with adjustable parame

ters (Gibbs energy of constituents, interaction parameters, etc.). The Gibbs energy parameters

are optimised in accordance with the experimental information in order to generate a self

consistent dataset of Gibbs energies of all phases in a system.

A new multipurpose thermodynamic database for oxide systems

119

Table 1

Liquid components (associate species) in the P containing systems

Description

System

Associate species with P2O5

MeO

x : P2O5

MeO2-P2O5 with Me = Si, Ti

SiP2O7 · 2/3, Si3P4O16 · 2/7, TiP2O7 · 2/3,

1 : 1, 3 : 2

Me2O3-P2O5 with Me = Al, Cr, Fe

AlPO4, CrPO4, FePO4

1 : 1

MeO-P2O5 with Mn = Mg, Ca, Fe, Zn

Me3P2O8 · 2/5, Me2P2O7 · 1/2, MeP2O6 · 2/3

3 : 1, 2 : 1, 1 : 1

Alk2O-P2O5 with Alk = Na, K

Alk3PO4 · 1/2, Alk4P2O7 · 1/3, AlkPO3

3 : 1, 2 : 1, 1 : 1

The database, called GTOX, is under constant development and at present covers the fol

lowing oxide and sulphide components: Al2O3-Al2S3-CaO-CaF2-CaS-CrOx-FeOx-FeS-

MgO-MgS-MnOx-MnS-K2O-K2S-Na2O-Na2S-NiO-P2O5-SiO2-SO3-TiOx-VOx.

DATABASE APPLICATION

In the following examples of application calculations using the GTOX database will be pre

sented.

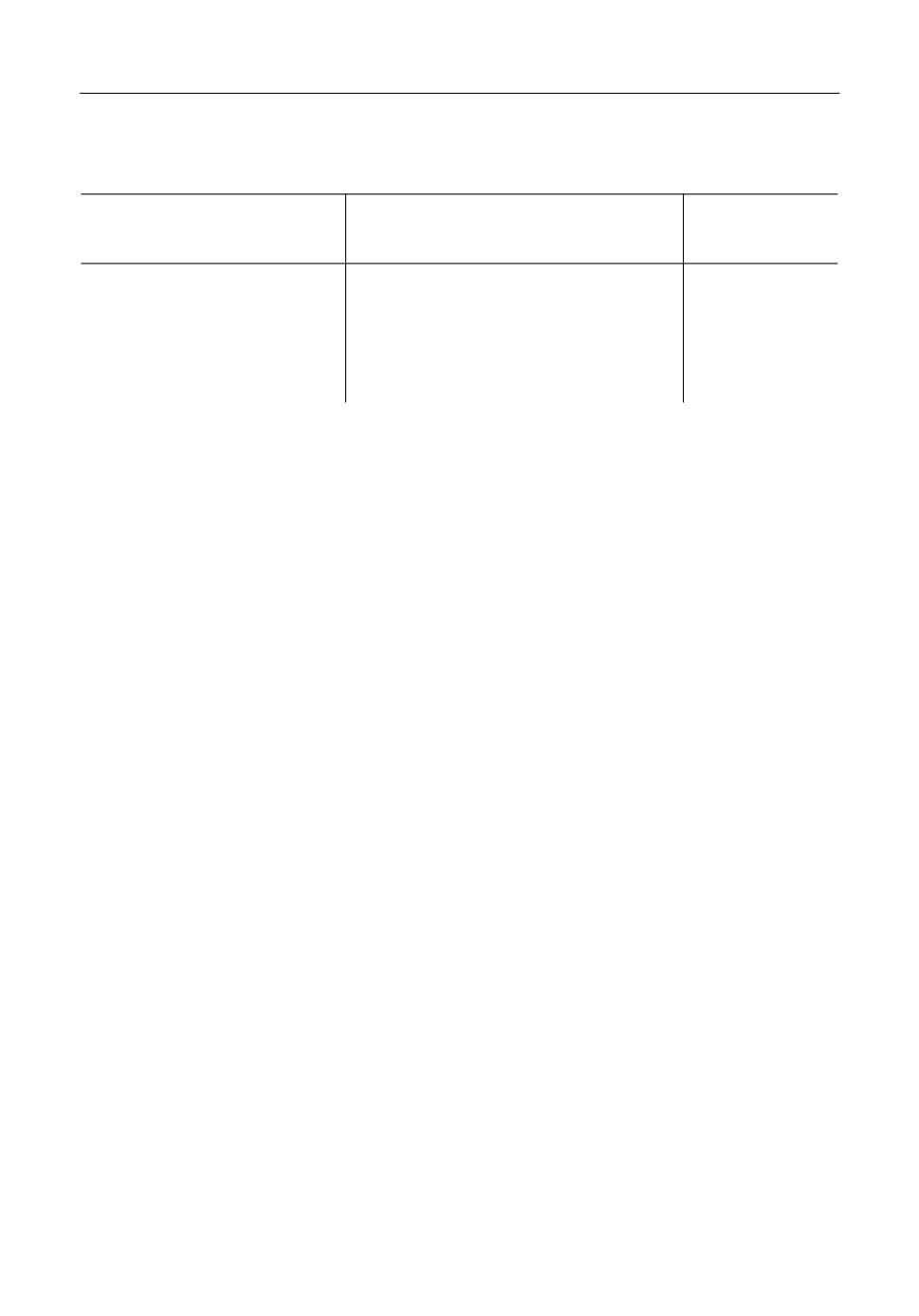

Slagging and fouling. An effective use of the world’s fossil fuels is obligatory in terms of their

limited supply and the worldwide increase in demand for energy. Hence, a fundamental

knowledge of the thermophysical and thermochemical processes during the conversion of the

fuel is necessary. Combustion and gasification request an essential understanding of the prop

erties of the inorganic residue (ash). The high temperature causes the ash to melt and, there

fore, the slag characteristically influences the conditions and limitations of the processes. The

behaviour of the liquid phase (melting temperature, crystallisation on cooling) is strongly de

pendent on the overall composition of the fuel (coal, biomass) and, particularly, of the residual

mineral part (ash). Thermodynamic calculations with reliable thermodynamic data can be

helpful in modelling the processes depending on various parameters (temperature, partial

pressure of oxygen, etc.). Table 2 shows the compositions of several ashes from different hard

coals. Taking into account all possible transitions occurring in the system (phase formation

and decomposition, melting, structure transitions, etc.) it is possible to represent the fraction

(in wt %) of the liquid phase as a function of temperature (Fig. 3). The ash SKK containing

the highest amount of alumina and CaO and the smallest one of SiO2 is predicted to begin

melting at higher temperature (about 870°C) compared to the other compositions. The liquid

us temperature (mass fraction of liquid = 100%) is higher as well (1400°C) due to the high

melting temperature of alumosilicates. The SKC composition on the other hand, with mini

mal content of CaO and Al2O3 and maximal SiO2 has a low melting range (onset at 750 and

end at 1150°C). The phase transitions can be calculated in order to describe the processes un

der cooling or heating at equilibrium conditions. Slagging and fouling in a coal fired power

plant (formation of liquid and/or solid deposits) are determined by the composition of the con

densed phases formed. Furthermore, the composition and formation temperature of solid phas

es influence the thermochemical and thermophysical properties of the slag (e.g. viscosity).

Dephosphorization. Dephosphorisation of steels by a metal slag reaction is important for

the steelmaking chemistry. The GTOX database can be used in this application field for the

calculation of dephosphorisation equilibria between slag and iron melts determining the equi

librium distribution of phosphorus between slag and metal for basic slags of various composi

120

E. Yazhenskikh, T. Jantzen, K. Hack, M. Müller

100

90

SKK

80

SKR

70

60

SKU

SKC

50

40

30

20

10

0

700

800

900

1000

1100

1200

1300

1400

T, °C

Fig. 3. Melting of different ashes (hard coals).

tions. A critical thermodynamic aspect of these processes is the equilibrium phosphorus parti

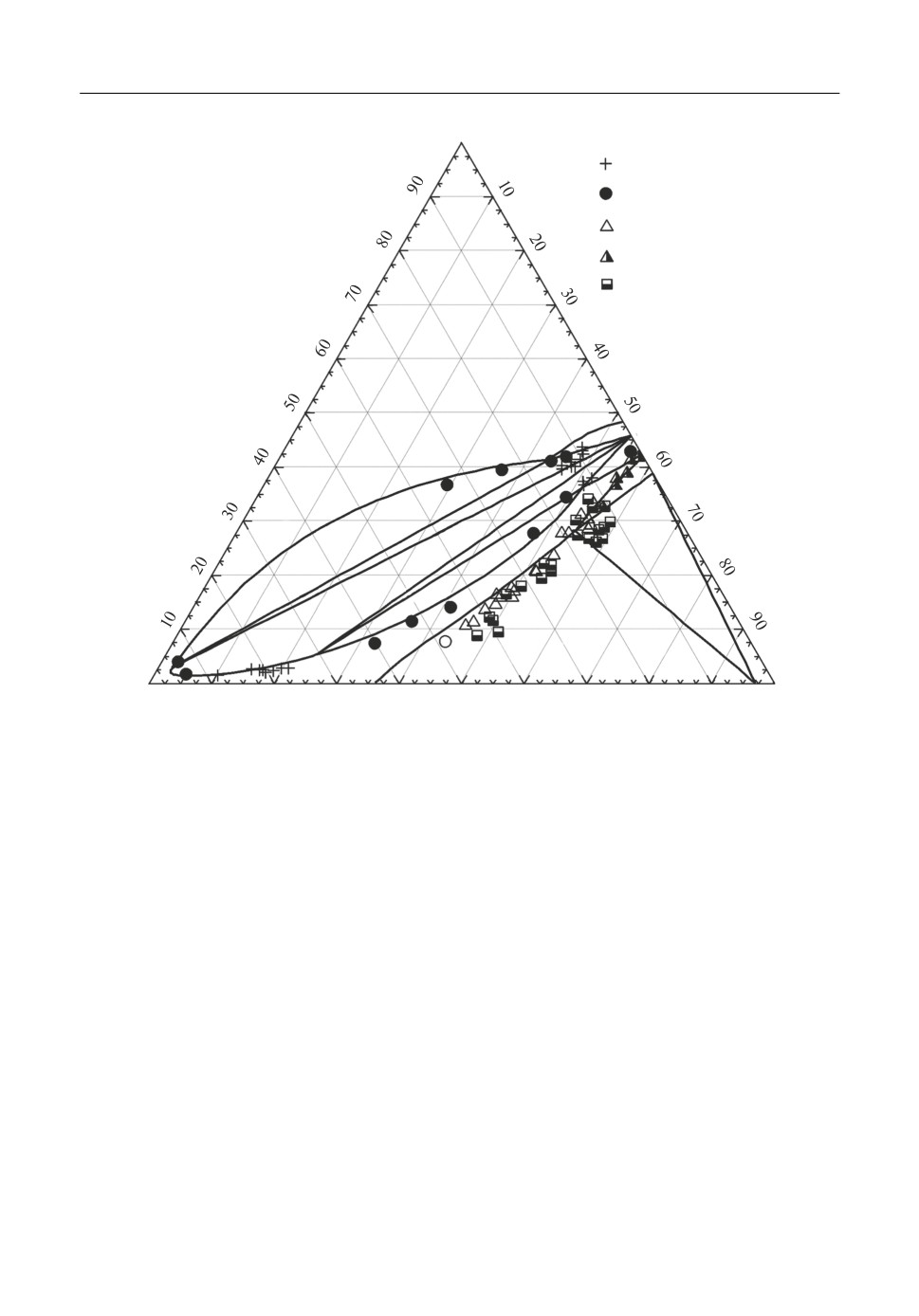

tion ratios Lp(%P)Slag/[%P]Fe) between slag and metal. The ternary CaO-FeO-P2O5 system is

a most important system for the Basic Oxygen Furnace (BOF) process. This system is charac

terized by a wide field of immiscibility extending in the liquid phase towards the FeO rich cor

ner reported by many investigators [10, 11]. The calculated isothermal section at 1600°C pre

Table 2

Compositions (in wt %) of the ashes

Columbia

South Africa

Russia

USA

Oxides

SKC

SKK

SKR

SKU

Al2O3

14.6

25.9

22.1

20.6

CaO

2.1

7.1

4.9

3.7

Fe2O3

15.5

15.4

6.8

14.6

K2O

1.4

0.7

2.9

2.4

MgO

1.1

0.1

0.2

0.9

Na2O

1.8

0.2

1.3

0.7

P2O5

0.1

1.5

0.5

0.2

SiO2

60.7

45.4

57.1

52.6

SO3

1.9

2.5

3.2

3.0

TiO2

0.8

1.4

0.9

1.1

A new multipurpose thermodynamic database for oxide systems

121

P2O5

[10]

[11]

CaO, [12]

CaO + Ca4P2O9, [12]

[13]

Slag + Liquid

C3P(s2)

C4P

Slag + Slag#2 + Liquid

Slag + Liquid + C3P(s3)

MeO + Slag + Liquid

FeO

90

80

70

60

50

40

30

20

10

CaO

percent by weight

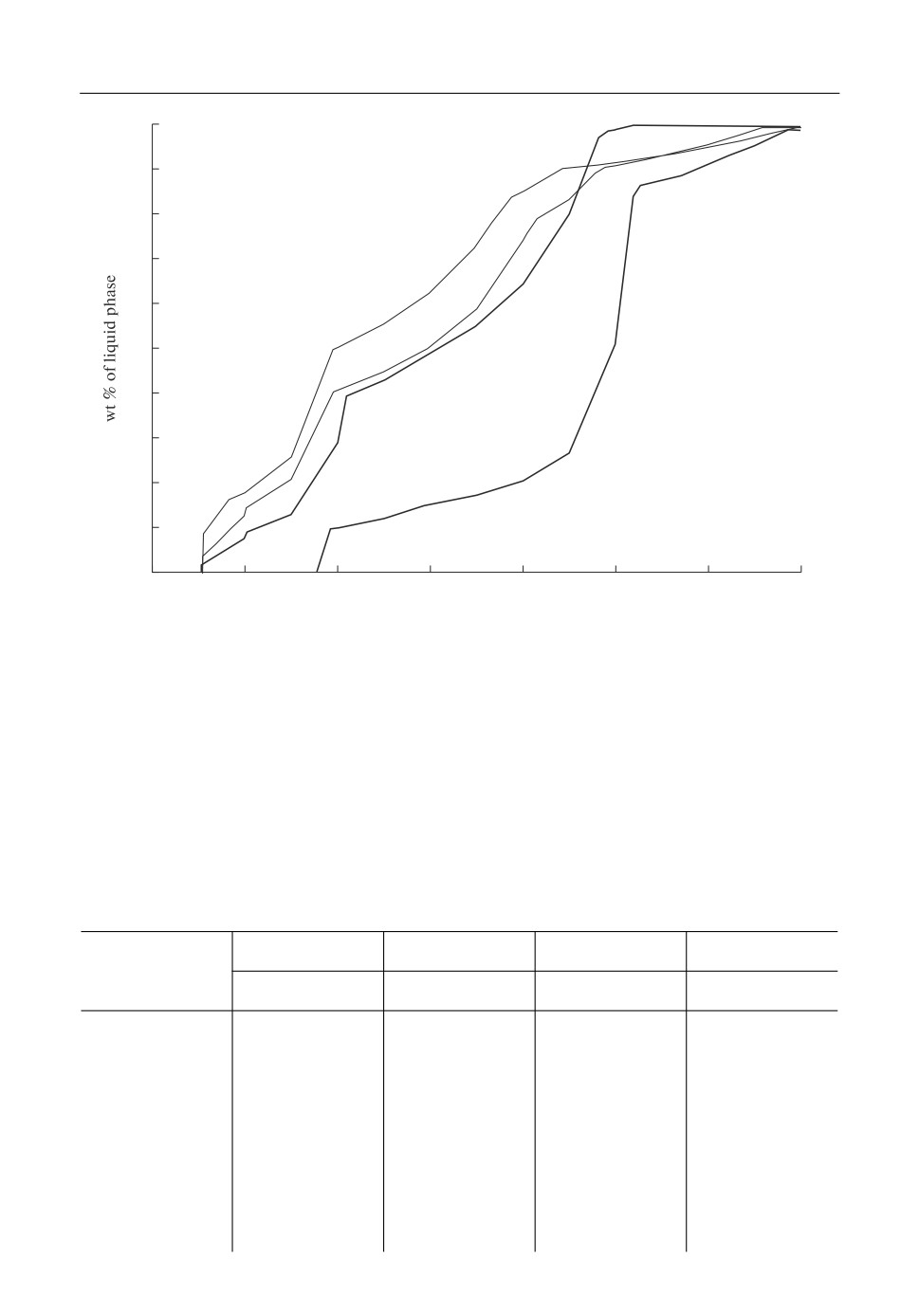

Fig. 4. Isothermal section at 1500°C in CaO-FeO-P2O5 system in equilibrium with Fe.

sented in Figure 4 is in good agreement with known experimental data [10-13]. The phospho

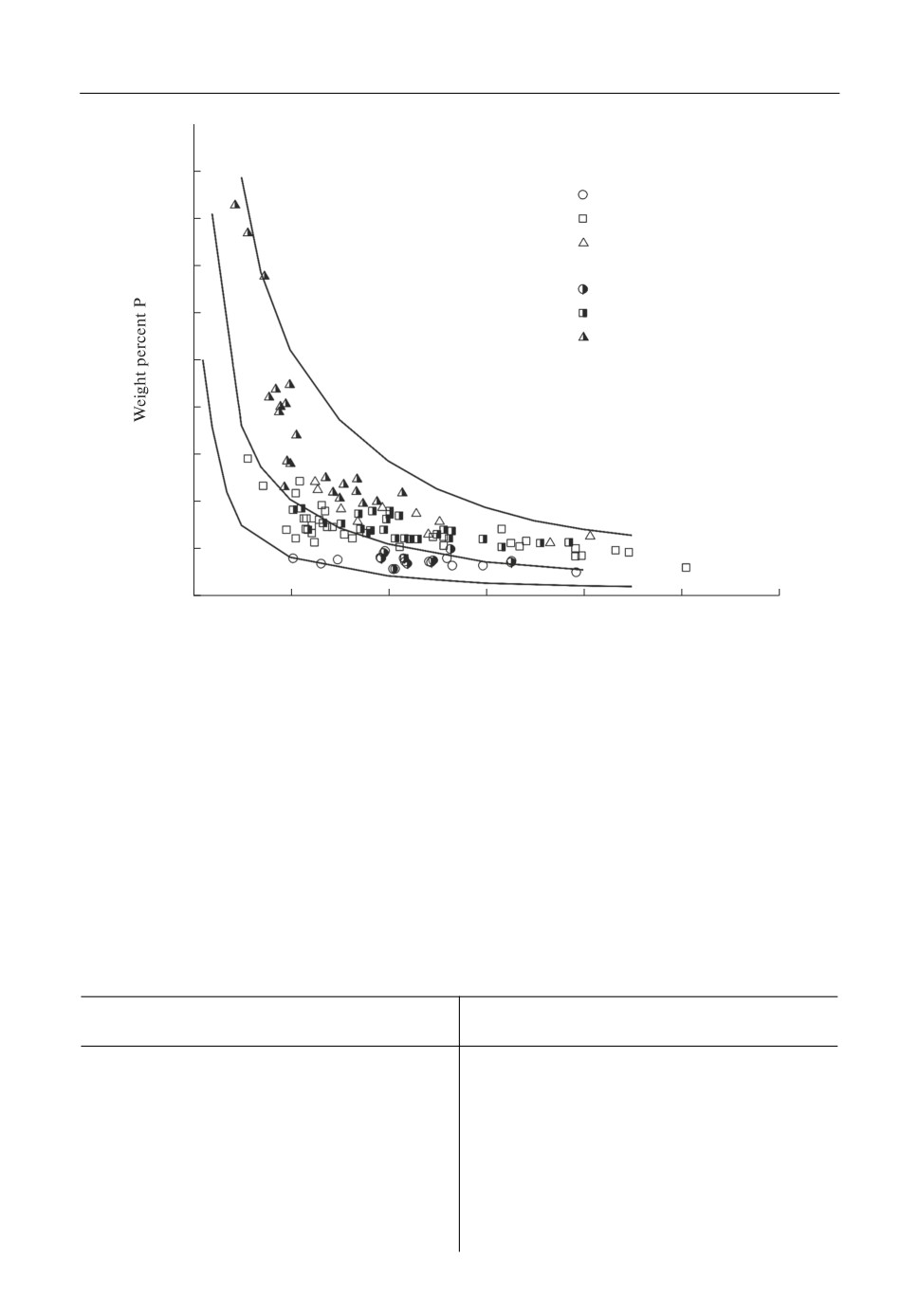

rus distribution between molten slag and liquid Fe in the CaO FeO P2O5 system along the

CaO saturation was studied by several researchers in the temperature range 1550-1650°C

[13, 14]. Figure 5 shows the relationship between the amount of phosphorus in liquid iron and

the content of FeO in CaO saturated molten slags at different temperatures. The phosphorous

concentration in liquid Fe depends on the temperature and the amount of FeO in the molten

slag. It increases with increasing temperature and decreasing amount of FeO. The experimen

tal behaviour could be well reproduced by the calculations (Fig. 5).

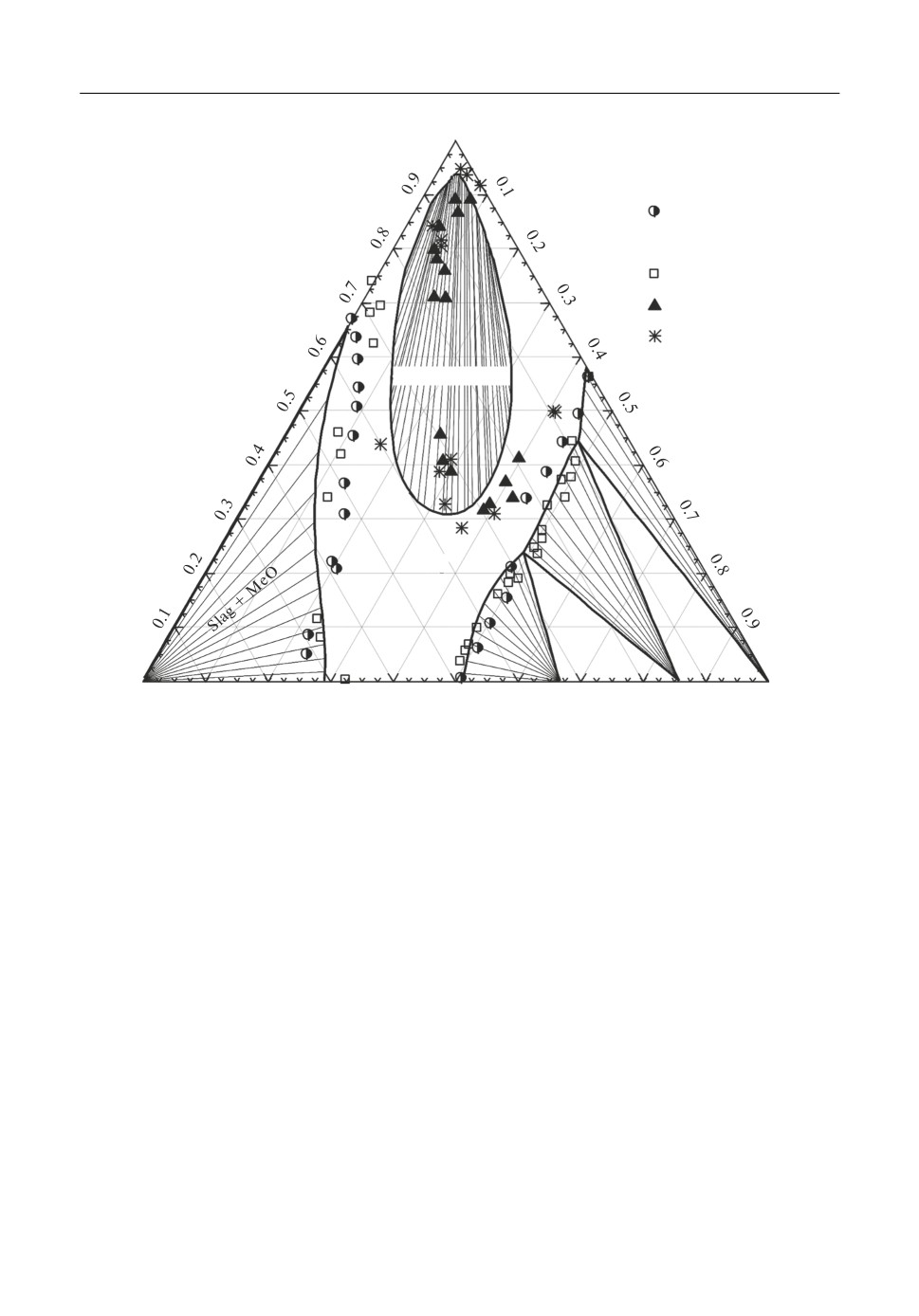

Inclusion of CaF2. An other important non oxide addition in the GTOX oxide database is

Fluorspar (CaF2) because of its wide application in ladle treatment of steel and especially elec

trometallurgy. The addition of CaF2 decreases the melting temperature and furthermore the

viscosity of the slags. Figure 6 shows the isothermal section at 1600°C through the Al2O3-

CaO-CaF2 system compared with experimental data [15, 16]. The calculated lines of satura

tion with CaO, Al2O3, CA6 and CA2 are in good agreement with experimental data, also the

computed wide zone of liquid immiscibility in the high fluoride region.

Addition of sulphur. Sulfur is commonly contained as an essential component in many natu

ral and manufactured materials. Sulfide glasses can be used for high refractory index materials.

122

E. Yazhenskikh, T. Jantzen, K. Hack, M. Müller

0.10

[13]

0.09

1550°C

0.08

1600°C

1650°C

0.07

[14]

1550°C

0.06

1600°C

1650°C

1650°C

0.05

1600°C

0.04

1550°C

0.03

0.02

0.01

0

10

20

30

40

50

60

Weight percent FeO

Fig. 5. Relationship between [%P] in liquid Fe and (FeO) in slag.

Sulfur species are present in radioactive and toxic wastes. Sulfides are in focus of attention due

to their importance for ferrous and copper metallurgical processes. The thermal properties

and stability ranges of sulfide containing systems is necessary for understanding and control of

the processes of desulfurization of molten alloys and precipitation of the sulfides during the

solidification process. The Ca-Cr-Fe-Mg-Mn-S sulfide sub system in combination with

corresponding oxides is part of the GTOX database (Table 3) and can be used and can be used

for thermodynamic calculations [4].

Table 3

GTOX database

Contents

Year 2018

Binary systems

149

Ternary systems

131

Quaternary systems

7

Solid solution phases

117

Compounds

702

Slag Atlas pages

1001

A new multipurpose thermodynamic database for oxide systems

123

CaF2

[15]

[16]

Phase boundry

Two liquids

One liquid

Slag + Slag#2

Slag

CaO

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

Al2O3

Mole fraction

CaAl4O7

CaAl

12O19

Fig. 6. Isothermal section at 1600°C in Al2O3-CaO-CaF2 system.

CONCLUSIONS

A self consistent thermodynamic database for the system Al2O3-Al2S3-CaO-CaF2-CaS-

CrOx-FeOx-FeS-MgO-MgS-MnOx-MnS-K2O-K2S-Na2O-Na2S-NiO-P2O5-SiO2-

SO3-TiOx-VOx which permits the calculation of phase diagrams and thermodynamic proper

ties for any composition and temperature has been established. Phase diagrams calculated us

ing this database show generally good agreement with the experimental phase boundaries. All

phase diagrams assessed are presented in a Slag Atlas provided by GTT Technologies in the

framework of the HotVeGas project [17]. The database obtained is successfully used in a very

wide range of applications (coal combustion and gasification metallurgy, dephosphorization,

fluxing, viscosity modelling).

ACKNOWLEDGEMENTS

Both GTT technologies and IEK 2, Forschungszentrum Jülich, gratefully acknowledge fi

nancial support of the HotVeGas project by the Ministry of Economic Affairs of the Federal

Republic of Germany under (FKZ 0327773L) and (FKZ 0327773K).

REFERENCES

124

E. Yazhenskikh, T. Jantzen, K. Hack, M. Müller

2. Hack K., Jantzen T., Müller M., Yazhenskikh E., Wu G. A novel thermodynamic database for

slag systems and refractory materials // Proceedings of the 5th Int. Congress on the Science and Tech

nology of Steelmaking. ICS 2012. Dresden. Germany. 2012.

3. Yazhenskikh E., Jantzen T., Hack K., Müller M. Critical thermodynamic evaluation of oxide

system relevant to fuel ashes and slags: Potassium oxide magnesium oxide silica // Calphad. 2014. 47.

P. 35-49.

4. Jantzen T., Hack K., Yazhenskikh E., Müller M. Evaluation of thermodynamic data and phase

equilibria in the system Ca-Cr-Cu-Fe-Mg-Mn-S: Part I: Binary and quasi binary subsystems //

Calphad. 2016. 56. P. 270-285; Part II: Ternary and quasi ternary subsystems // Calphad. 2017. 56.

P. 286-302.

5. Pearson W.B. A Handbook of Lattice Spacings and Structures of Metals and Alloys. Pergamon

Press, Oxford. 1967. V. 2.

6. Fix W., Heymann H., Heinke R. Subsolidus relations in the system 2CaO · SiO2-3CaO · P2O5 //

J. Am. Ceram. Soc. 1969. 52. № 6. P. 346-347.

7. Eke M., Brett N.H. Phase equilibriums in the system CaO-MgO-SiO2-V2O5 // Trans. J. Br.

Ceram. Soc. 1973. 72. № 5. P. 195-201.

8. Besmann T.M., Spear K.E. Thermodynamic modelling of oxide glasses. // J. Am. Ceram. Soc.

2002. 85. № 12. P. 2887-2894.

9. Wu G., Seebold S., Yazhenskikh E., Hack K., Müller M. Viscosity model for oxide melts rele

vant to fuel slags. Part 3: The iron oxide containing low order systems in the system SiO2-Al2O3-

CaO-MgO-Na2O-K2O-FeO-Fe2O3 // Fuel Processing Technology. 2018. 171. P. 339-349.

10. Trömmel G., Fritze H.W. Equilibriums between iron and lime containing phosphate slags. //

Arch. Eisenhüttenwes. 1959. 30. P. 461-472.

11. Turkdogan E.T., Pearson J. Activities of constituents of iron and steelmaking slags. III Phos

phorus pentoxide. // J. Iron Steel Inst. London 1953. 175. P. 398-401.

12. Trömmel G., Fix W. The equilibrium between an iron melt and lime containing phosphate

slags in the presence of silica and manganese oxide // Arch. Eisenhüttenwes. 1962. 33. P. 745-755.

13. Nagabayashi R., Hino M., Banya S. Distribution pf phosphorus between liquid iron and FetO-

(CaO+MgO)-(SiO2+P2O5) phosphate slags // Tetsu to Nagane. 1988. 74. P. 1770-1777.

14. Trömmel G., Fix W. The system lime phosphorus pentoxide // Arch. Eisenhüttenwes. 1961.

32. P. 209-272.

15. Zhmoidin G.I., Chatterjee A.K. Slags for Metal Refining. Properties Variations of System

CaO-Al2O3-CaF2 // Metallurgiya, Moscow. 1986. P. 286-296.

16. Ries R., Schwerdtfeger K. Contribution to the phase diagram calcium fluoride calcium oxide

alumina // Arch. Eisenhuettenwes. 1980. 51. № 4. P. 123-129.

17. Slag Atlas on request of GTT Technologies, info@gtt technologies.de.